Source: www.imgbuddy.com

A few posts ago, we discussed digital print and the benefits and limitations in comparison to traditional offset printing. Today, we explore the world of offset printing by explaining the process and how understanding this method can help you make a more informed decision regarding your ongoing printing requirements.

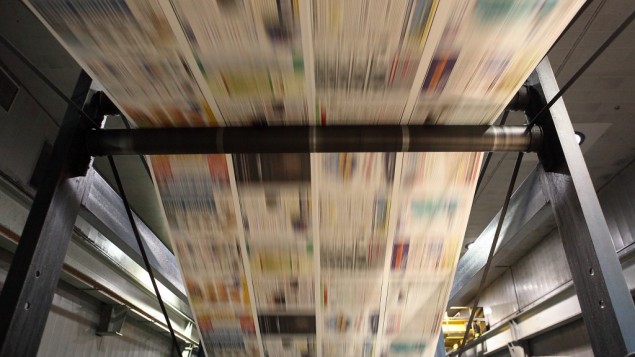

Offset printing is rich in history and really set the stage of its story in the early 1900’s. As you may have guessed from our previous post on digital print (read that blog post here), offset printing is ideal for larger print orders and is famous for servicing the newspaper, magazine and book industries. It is an economically sound alternative to digital and still holds its own in the world of print and the growing development of digital technology.

To put it as simply as possible, offset printing is the process of transferring an image that is burnt into a metal plate onto rubber rollers. Then, using these rubber rollers – the image is transferred onto the desired medium (paper, plastic etc.) To successfully transfer the image to paper, the rubber rollers are inked using ink pads that allow the image to then be replicated.

Offset printing uses both the CMYK (full colour) and Pantone colour matching systems which is ideal for those who require exact accuracy of colour every time (normally applicable for larger corporate organisations), or have artwork designed in single pantone colours.

Within the realm of offset print, you have two different methods available to select from. Firstly, there is sheet-fed offset printing which utilises large individual sheets of paper. This is usually for small-medium offset printing runs, given the individual nature of the sheet-fed process. The other option, and often the most popular choice is roll-fed or ‘web’ offset printing, which uses large machines and massive rolls of paper that are traditionally cut and separated after the printing has occurred.

Source: www.asiapacificoffset.com/

Offset printing, in comparison to digital printing

Typically, if your print quantity is small, you will find that offset printing can become an expensive option. Offset printing has an initial outlay of costs eg. Plates, Setup, Wash-up, etc, which gradually decreases the cost of each unit as the quantity requested increases. This is the main reason why newspapers, magazines and other large-scale publications are produced using the offset printing method, as it is proven to bring down the costs of each individual unit as the demand for the product grows. The quantity that you require really does determine what method of print is best for you.

Source: www.cattychef.com

Your designer & printer can often assist in selecting the best process for you, as we do for our clients, bearing in mind both cost, quality and time frame.

Have you had experiences with offset printing? We’d love to hear about it! If you have any questions, please feel free to comment below.

Hi,

I am publishing weekly magazine but we are a small quantity which is 1500 copies.

52gsm 120pages + 4 pages gross cover

Plz can i get a quotation?

Thanks

Categories

Comments